Robotic ImagingMay 31, 2023

The AEC industry has become a hotbed for virtual reality (VR) technology in recent years, and with good reason. VR can help save time, money and energy by reducing the need for physical measurements and testing. It also allows you to visualize your project before it's built — an invaluable tool that gives you greater peace of mind as you plan out your next big construction project. In this post we'll explore how virtual reality is being used in the AEC industry today, as well as some of its key advantages over manual documentation methods like taping off measurements on site.

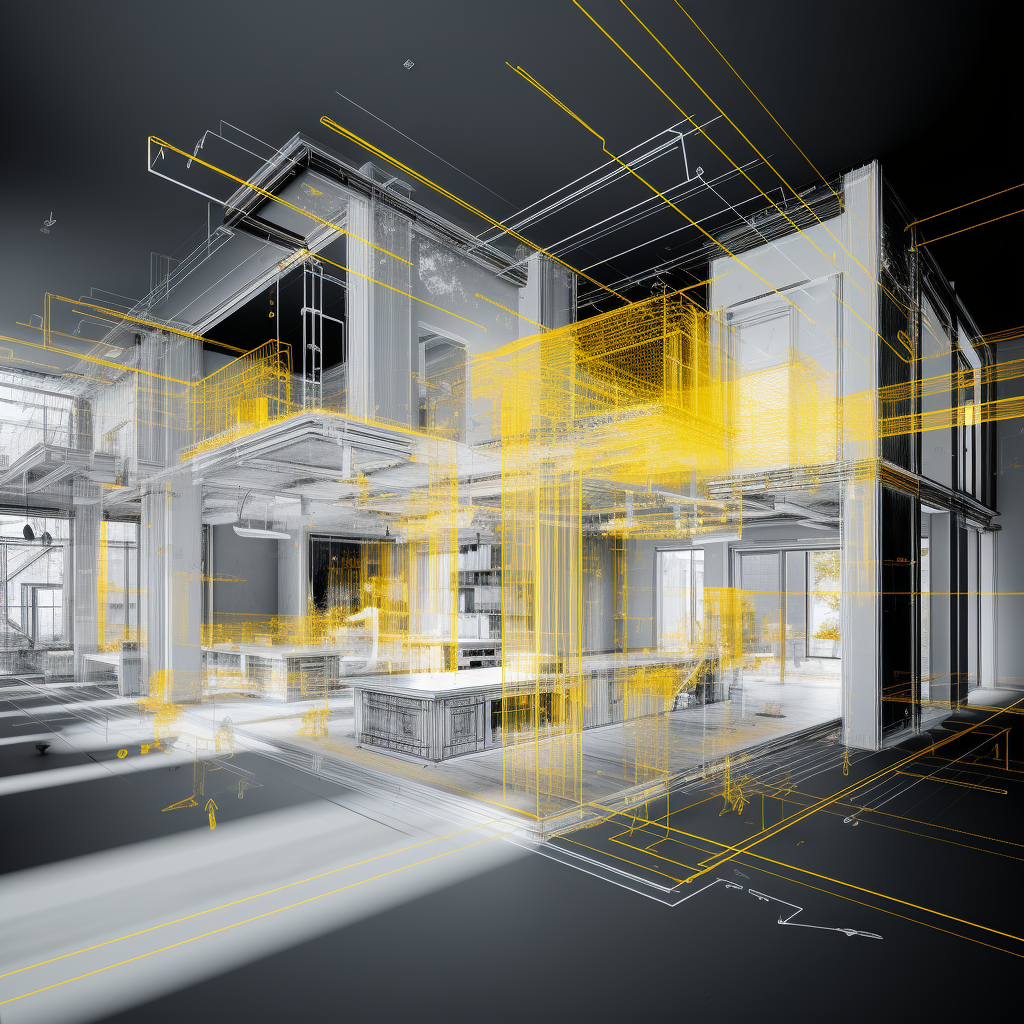

Virtual reality technology has revolutionized the way we approach construction projects. The ability to visualize a project before it's built can help save time, money, and energy by reducing the need for physical measurements and testing. This is where Robotic Imaging comes in, making the entire process more streamlined and efficient. VR is an excellent way to visualize a project before it's built. It can help you see how the finished product will look, how it will function, and how it will interact with its surrounding environment.

For example: The design of your new office space might include several open work areas as well as private meeting rooms. With VR technology, you'll be able to walk through each room before construction begins and decide if they need any changes--for example, adding more or less furniture than originally planned--to better accommodate your employees' needs. Or perhaps a new manufacturing plant may require specific equipment for production purposes; however these pieces of equipment need not necessarily be placed in plain view from all angles (for security reasons). Using virtual reality allows designers to move around in their environment without being limited by physical constraints such as walls or doors that would otherwise prevent them from seeing everything at once.

A single 3D model can provide context and scale while also reducing costs associated with on-site measurement and testing. With Robotic Imaging, it's possible to capture a space digitally in just a few minutes, creating a high-quality 3D model that can be used for virtual reality planning and design. This saves time and money compared to traditional surveying methods, which require a lot of physical effort and time. Using a virtual model to explore a project before it's built can help you make decisions earlier, reduce costs by avoiding design changes later in the process, and potentially even increase your profit margins.

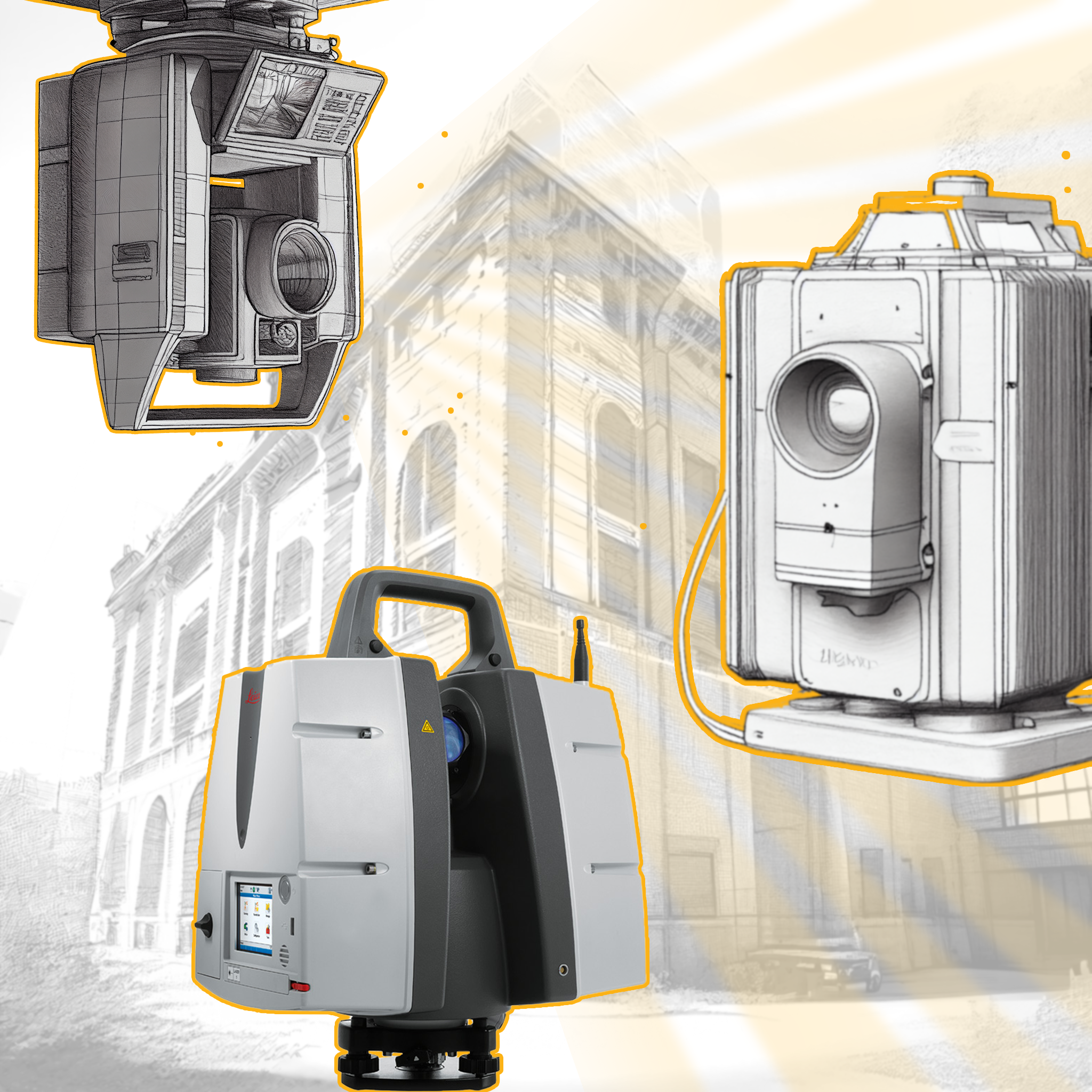

The technology behind Robotic Imaging has come a long way in recent years, allowing for more accurate and detailed scans. Matterport cameras, for example, can capture a vast number of angles around each subject they scan, including floors, ceilings, and walls. Using a Matterport camera allows you to capture an entire room or building in less than 10 minutes, which means physical effort can be minimized (and risk reduced). This provides architects and designers with a more complete picture of the space, enabling them to make more informed decisions about the project.

Capturing your building digitally has several benefits over traditional field surveys and manual documentation methods such as taping off measurements on site. There is no need to physically measure a space: With virtual reality, you can walk through a building without having to physically measure a single point. This saves time and money because there's no need for multiple people going back-and-forth between points in order to capture them all; it also eliminates errors that may occur when one person measures something different from another person (e.g., if two people try measuring the same wall but use slightly different techniques).

But Robotic Imaging isn't just about creating accurate 3D models using our LiDAR scanners in conjunction with VR scanners. It's also about providing a better experience for clients. With virtual reality, clients can walk through a building before it's built, getting a feel for the space and making any necessary changes before construction even begins. This not only saves time and money but also increases client satisfaction.

By hiring a company like Robotic Imaging to handle all of your virtual reality needs, you can take your AEC projects to the next level. With our expertise in LiDAR and virtual reality data capture, we can create high-quality 3D models that accurately reflect your project, making it easier for you to make informed decisions about the design and layout.

In conclusion, virtual reality is transforming the AEC industry, and Robotic Imaging is leading the way. To summarize, virtual Reality is becoming more common within the AEC industry for its ability to both speed up as-built documentation processes and reduce costs associated with on-site measurement and testing. With the ability to capture accurate and detailed 3D models in just a few minutes, and the ability to provide clients with a virtual walkthrough of their project, it's clear that this technology is here to stay. So why not take advantage of it? Reach out to Robotic Imaging today for a free quote and to see how they can help take your AEC projects to the next level.